Management of Environmental Responsibility

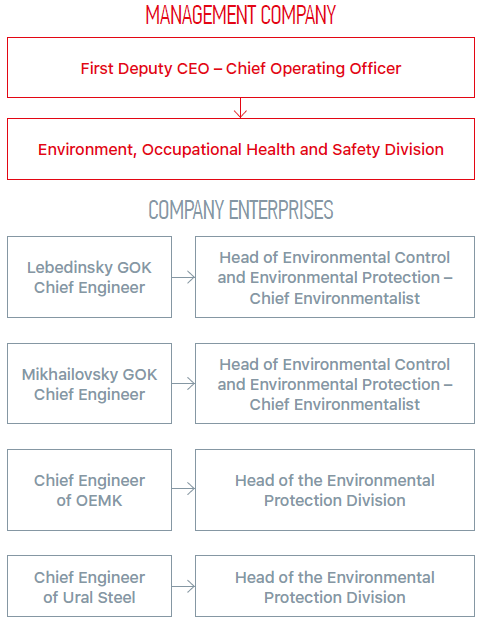

Environmental responsibility issues are managed as part of a two-tier system: at the level of the Management Company and at the level of enterprises. At the Management Company level, the First Deputy CEO and Production Director and the Environment, Occupational Health and Safety Division coordinate environmental protection issues. At enterprises, chief engineers and the core units under their control are responsible for environmental protection activities.

Environmental protection issues as well as the Company’s goals for environmental responsibility are enshrined in the Health, Safety and Environment Policy. The Company’s primary goal in this regard is to reduce its environment impact through the following objectives:

- continuously developing and improving production processes;

- sustainable use of production and natural resources;

- improving the efficiency of industrial environmental monitoring;

- compliance with environmental legislation.

Metalloinvest carries out a number of measures to achieve these objectives such as investing heavily in environmental protection activities and improving the technologies it uses.

The Company’s expenses on environmental protection amounted to RUB 7.2 billion during the reporting period, a 10% increase compared with the previous reporting period. Of this amount, RUB 1.3 billion were spent on the retrofitting of enterprises. In total, the Company’s expenditures on environmental protection measures and investment in environmental protection amounted to RUB 37 billion in 2014–2018.

All the Company’s enterprises have environmental management systems. In order to ensure compliance with the Company’s high environmental protection standards and environmental legislation, internal corporate inspections of environmental management activities and management systems are carried out at all the Company’s plants. Corrective measures are taken based on the results of inspections to improve the existing environmental management systems.

In addition to internal corporate inspections, the Company conducts industrial environmental monitoring as well as internal and external audits of the environmental management system. An external audit carried out during the reporting period reaffirmed that the Company’s environmental management systems and integrated management systems comply with the requirements of ISO 14001:2015.

External supervisory authorities also conducted a number of inspections during the reporting period, which revealed a few areas of noncompliance with environmental legislation. The Company was fined a total of RUB 200,000. All the violations found were investigated and rectified. A set of preventive measures was developed in each case to prevent violations in the future.

307-1

Such measures include, for example, regular monitoring of changes in legislative requirements and the annual training of employees who are responsible for environmental issues at the enterprises as part of seminars on environmental legislation, which are also attended by government representatives.

Metalloinvest’s high level of awareness of changes to the aforementioned requirements resulted in the all the holding’s enterprises complying with future requirements of Russian environmental protection legislation as well as the integration of the best available technologies (BAT) during the construction and modernisation stages of production facilities. This approach ensures sequential ecological and technical transformation and a reduction in the environmental impact. In addition, information and technical reference guides on BAT were drafted with Metalloinvest’s support on such issues as Iron Ore Mining and Processing, Pig Iron, Steel, and Ferroalloy Production, and Ferrous Metal Downstream Production.

Drafting of scientific and technical reference guides on the best available technologies

In accordance with Federal Law No. 219-FZ dated 21 July 2014 On Amendments to the Federal Law on Environmental Protection and Certain Legislative Acts of the Russian Federation, all ferrous metals enterprises must switch to the use of BAT that are specific to each type of activity and described in the BAT reference guides in the period from 1 January 2019 to 1 January 2025. Sharing environmental values and promoting environmental legislative activities, Metalloinvest supported the drafting of the guides and one of the Company’s representatives chaired the Working Group that prepared them.

In addition to describing the industries and their typical technological processes, the guides include a list of the best available technologies that can be used to help reduce the impact in each particular industry and set targets for their use.

All the Company’s enterprises confirmed compliance with all the requirements specified in the BAT reference guides during the reporting period and thus confirmed compliance with the legislative requirements.

The Company not only provides awareness about the importance of environmental issues at the management level, but also at the level of all enterprise employees with a series of informational events that includes monthly committee meetings on occupational health and safety and environmental safety, briefings of directors, reports by managers, a quarterly summary of the results of monitoring procedures, and an annual corporate seminar on occupational health and safety and environmental safety.

In addition, the Company does not neglect the interests of external stakeholders and engages them by providing periodic reports and organising public hearings on issues concerning the assessment of the environmental impact of the Company’s current and planned activities.

Effective feedback mechanisms with internal and external stakeholders on issues concerning environmental responsibility received high marks in the WWF environmental responsibility rating in which the Company was ranked 6th among Russian mining and steel companies.

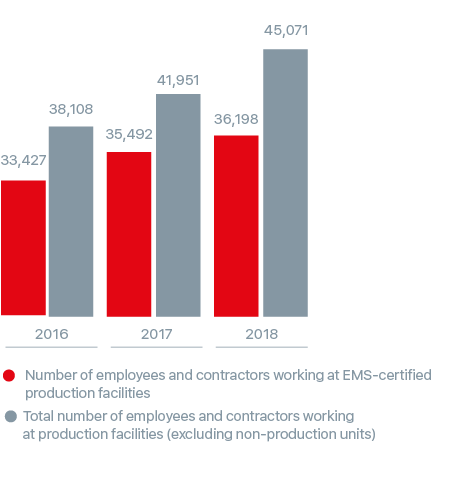

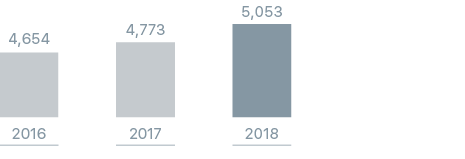

The Company’s commitment to managing environmental responsibility is confirmed by Metalloinvest’s use of EMS-certified production facilities. The share of employees and contractors working at EMS-certified facilities remains consistently high and amounted to 80% of the total headcount in 2018. EMS-certified production facilities manufactured a total of 5,053 thousand tonnes of steel. Thus, all manufactured steel is 100% certified in accordance with ISO 14001 certificates.