Water Consumption and Protection

303-1Metalloinvest strives to increase the amount of water it recycles and reuses in an effort to reduce the impact on water bodies. The Company uses special settling tanks whose equipment prevents used water from penetrating the soil. Wastewater stored in tanks is used as process water.

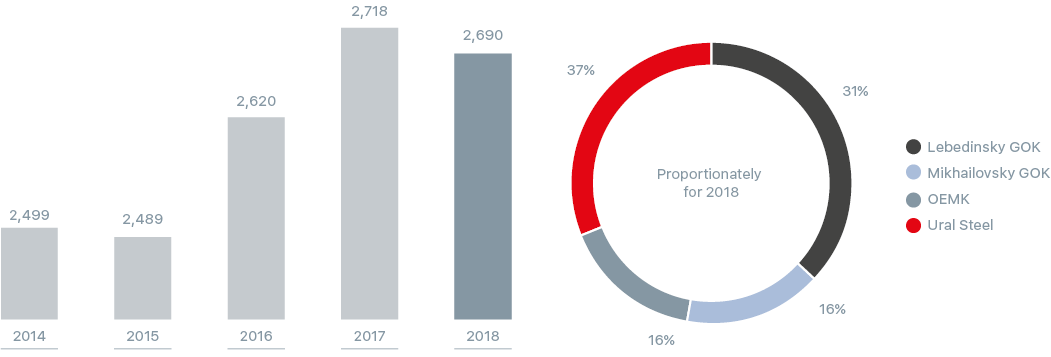

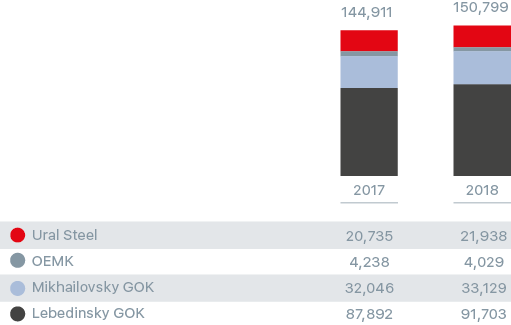

Overall water consumption increased compared with the previous reporting period due to the scaling up of production, while the share of water consumed amounted to 5.6% of the total volume of water recycled and reused. Most of the water consumption is used to cool furnaces and equipment, a process in which no water pollution occurs.

The total volume of water reused at plants is calculated using water balance estimation in the water recycling systems.

303-1

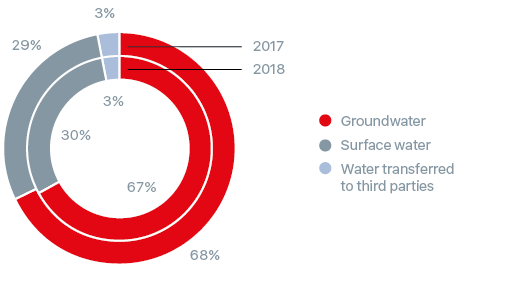

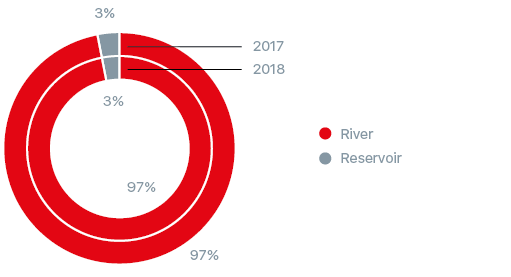

Metalloinvest enterprises receive water for industrial needs and drinking water supply from surface and groundwater. The main sources of water intake and wastewater discharge are rivers (Oskol, Oskolets, Ryasnik, Chern, Rechitsa, and Ural) and a reservoir (Starooskolsky reservoir) located in the regions where the plants operate.

There are no water shortage in any regions from which water is taken.

The Company does not use formation or sea water, and all the water it takes is classified as fresh.

303-1

The Company pays significant attention to compliance with water usage conditions and takes a responsible approach to monitoring its impact on water resources. In particular, the Company’s accredited in-house laboratories monitor and analyse the content of pollutants both in intake water as well as wastewater on a monthly basis. In addition, the Company maintains strict records of water intake and monitors the condition of water bodies and their water protection zones within which it carries out diving surveys of fish protection structures at water intakes each year, among other measures.

306-1

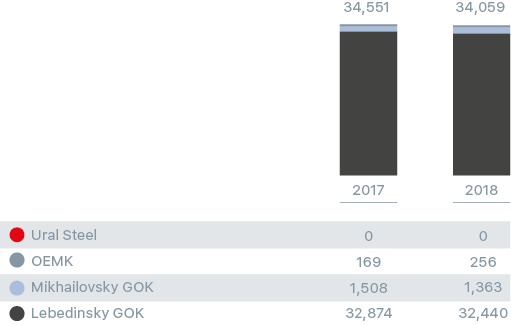

Wastewater discharge edged down slightly in 2018 compared with the previous year and amounted to 34,060,000 m3. The Company carries out timely and effective measures to prevent accidents at water bodies. No unplanned wastewater discharge was carried out in 2018.

Prior to being discharged, the entire volume of polluted water was treated at sewage treatment plants using biological, mechanical, physical, and mechanical methods, which significantly reduced the impact of Metalloinvest’s plants on the biodiversity of water bodies.

303-2

All the Company’s wastewater complies with state and municipal quality standards as well as the internal monitoring programme for water bodies and their water protection zones and is discharged within the prescribed limits.

The main body of water into which water is discharged is the Oskolets River near Lebedinsky GOK, and the quality of the wastewater is much higher than the quality of water in the river itself.

306-1

Ural Steel does not discharge wastewater. All wastewater discharges were planned.

306-1| Lebedinsky GOK | Mikhailovsky GOK |

OEMK | Wastewater discharge volume using treatment method |

|||

|---|---|---|---|---|---|---|

| Wastewater treatment method | 2018 | 2018 | 2017 | |||

| On-site storage, including | 18,092 | 889 | 256 | 19,237 | 18,544 | |

| Biological treatment | 19 | 0 | 0 | 19 | 26 | |

| Physical and mechanical treatment | 0 | 0 | 256 | 256 | 169 | |

| Mechanical treatment | 18,073 | 889 | 0 | 18,962 | 18,349 | |

| Untreated wastewater | 0 | 0 | 0 | 0 | 0 | |

| Effluents | 0 | 0 | 0 | 0 | 16 | |

| Standard clean (untreated) | 14,348 | 474 | 0 | 14,822 | 15,991 | |

| Total wastewater discharge by facility | 32,440 | 1,363 | 256 | 34,059 | 34,551 | |

Ural Steel does not discharge wastewater.

306-1

Greywater is transferred to municipal wastewater services for further treatment. A total of 12,280,000 m3 of wastewater was transferred to municipal services during the reporting period, which is 8% less than in the previous year.

Key water consumption measures

Retrofitting cooling water circuits at OEMK

In December 2018, OEMK completed the retrofitting of its 5th and 6th cooling water circuits. The project ensures uninterrupted water supply for the closed cycle and the simultaneous operation of five continuous casting machines (CCMs). The modernisation of the water circuits helped to reduce the volume of water taken and discharged while increasing production.

Process water recycling system at Mikhailovsky GOK

A project was launched in the fourth quarter of 2018 to equip the crushing and screening plant (CSP) at Mikhailovsky GOK with a recycling water supply system. The project will eliminate wastewater discharges into the Ryasnik River.

Creation of a water protection zone in the Chern River at Mikhailovsky GOK

This measure was carried out to eliminate the risk of pollution of the Chern River.

Plans for 2019

Due to an expansion in production, the Company’s top priority is to maintain the level of water intake and water consumption at the current level in accordance with the short-term environmental objectives of the Group’s enterprises for 2019.

The Company plans to continue work to equip the crushing and screening plant (CSP) at Mikhailovsky GOK with a process water recycling system.