Energy Consumption and Efficiency

Metalloinvest takes energy consumption very seriously and is committed to improving energy efficiency as its business constantly evolves and production increases. All the Company’s enterprises have been certified with ISO 50011 Energy management and meet international energy efficiency requirements.

The Company adjusts its Energy Efficiency Improvement Strategy in accordance with its current business objectives on an annual basis. The current version of the Strategy was adopted until 2023 and makes energy efficiency a key parameter in the Company’s investment projects. The Strategy states that energy efficiency should be integrated with production management system at Metalloinvest’s plants during the design stages.

Energy efficiency measures help to reduce growth rates in fuel and electricity consumption. This is particularly important when scaling up production by introducing new equipment and building new facilities, which traditionally involves high energy consumption. Taking into account the results of measures that were adopted to increase energy efficiency, fuel and electricity consumption increased by 1% and 3% in 2018 accordingly.

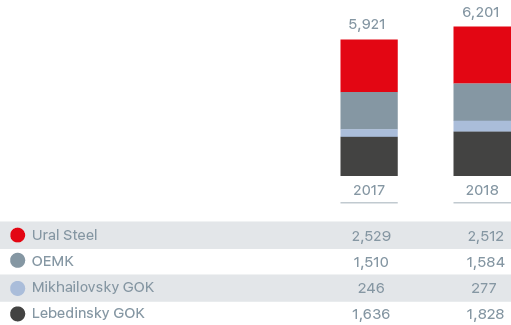

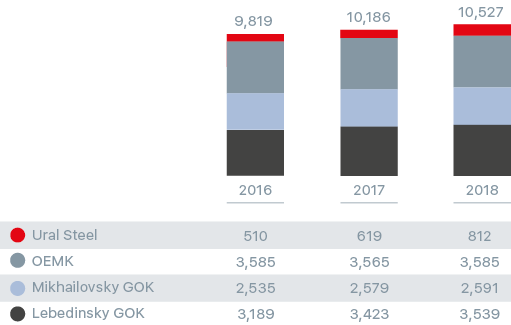

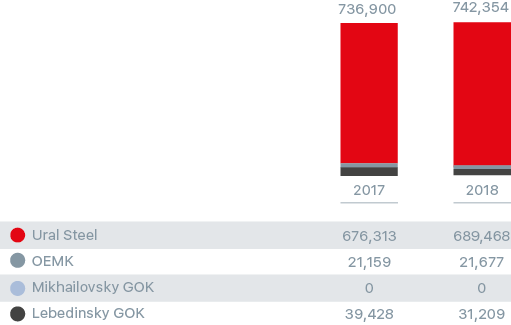

302-1[tonnes of oil equivalent]

The conversion to kJ may be performed using the following ratio: 1 GW h = 3,600,000,000 kJ.

Data on electricity consumption at Ural Steel does not take into account the consumption of electricity generated at its Ural Steel Combined Heat and Power Plant and Turbo Blower Station. Data for 2016 and 2017 was recalculated compared with the 2017 report.

| 2016 | 2017 | 2018 | 2018/2017 | |

|---|---|---|---|---|

| Coal | 2,034 | 1,717 | 1,45 | -15% |

| Fuel oil | 2 | 3 | 3 | 0% |

| Natural gas | 3,891 | 4,589 | 4,909 | +7% |

| Diesel fuel | 79 | 108 | 114 | +6% |

| TOTAL | 6,006 | 6,417 | 6,477 | +1% |

Fuel converted from natural physical units to tonnes of oil equivalent (TOE) in accordance with the ratios proposed by the Ratio Reference Book. Natural gas: ratio = 1.154; diesel: ratio = 1.45; coal: ratio = 0.768–0.876, depending on the deposit. The figure can be converted to kJ using the following ratio: 1 TOE = 29,307,600 kJ.

Energy consumption (coal, natural gas, and diesel fuel) directly depends on the production programme of enterprises and their plans for repair and maintenance work. During the reporting period, Metalloinvest continued to reduce the share of coal consumption as it gradually replaces it with natural gas. Fuel oil is mainly used as a backup fuel for boilers.

302-1| 2016 | 2017 | 2018 | |

|---|---|---|---|

| Coal | 33.87% | 26.76% | 23.96% |

| Fuel oil | 0.03% | 0.05% | 0.04% |

| Natural gas | 64.78% | 71.50% | 74.28% |

| Diesel fuel | 1.32% | 1.69% | 1.72% |

Metalloinvest does not sell electricity. The conversion to kJ may be performed using the following ratio: 1 Gcal = 4,187 kJ.

Key measures to improve energy efficiency

Measures to improve energy efficiency aim to accomplish two main goals: reducing energy consumption and reducing energy consumption costs.

- Development of internal generation technologies at production facilities to ensure the continuity of production processes in the event of disruptions in external power supply. The initiative includes the launch of projects to rebuild boiler houses at all the Company’s plants technologies. The initiative is expected to reduce the consumption of natural gas that is traditionally used as a resource for generation along with reducing emissions of greenhouse gas and harmful substances and also lower costs for the maintenance of obsolete equipment. A project was also initiated during the reporting period to modernise the CHP plant at Ural Steel, which entails installing medium-pressure boilers in order to use both natural and blast-furnace gas – a by-product of pig iron production – as a source of energy.

- Commissioning of the Lebedi substation as part of the reconstruction of the Lebedinsky GOK external power supply system, which resulted in significant savings in energy consumption costs. In the long term, the initiative also aims to provide the plant with a sufficient reserve of capacity in order to develop production.

Metalloinvest is an energy supplier in the Orenburg Region city of Novotroitsk where it supplies almost 100% of all energy.

Plans for 2019:

Metalloinvest initiated a study of the methods used for reactive power compensation. Unlike active power, which transforms electricity into useful forms of energy, reactive power consists of electricity that is mainly consumed for the ineffective heating of electricity conductors. The Company plans to consider ways to release useful energy from reactive power to increase the total capacity of production units. Examples of such units are diesel locomotives that transport ore from quarries. The increase in their traction power while not losing any speed will contribute to increased process efficiency and overall productivity.

Metalloinvest employees themselves make a significant contribution to improving the Company’s energy efficiency. Since 2011, an annual competition has been held for the best innovative proposal to improve energy efficiency. As part of the competition, employees individually or collectively prepare and submit their proposals, which are considered by special commissions at each of the plants. The best proposals are approved for future implementation and are included in the investment programme and the submitters of winning ideas are rewarded with a cash bonus.

Key facts of the competition for the best innovative proposal to improve energy efficiency

- 93 – the number of participants since the competition was launched in 2011

- 63 – the number of approved proposals since the competition was launched

- RUB 516.5 billion – total reduction of energy costs in monetary terms from 2011 to the end of 2018 due to the implementation of the innovative proposals

- 11 – the number of participants in the competition in 2018

- 11 – the number of approved proposals from the 2018 competition